هل تعرف حقًا مغناطيسات مكعب NDFEB N52؟ اقرأ هذا!

شارك

Table Of Content

Table Of Content

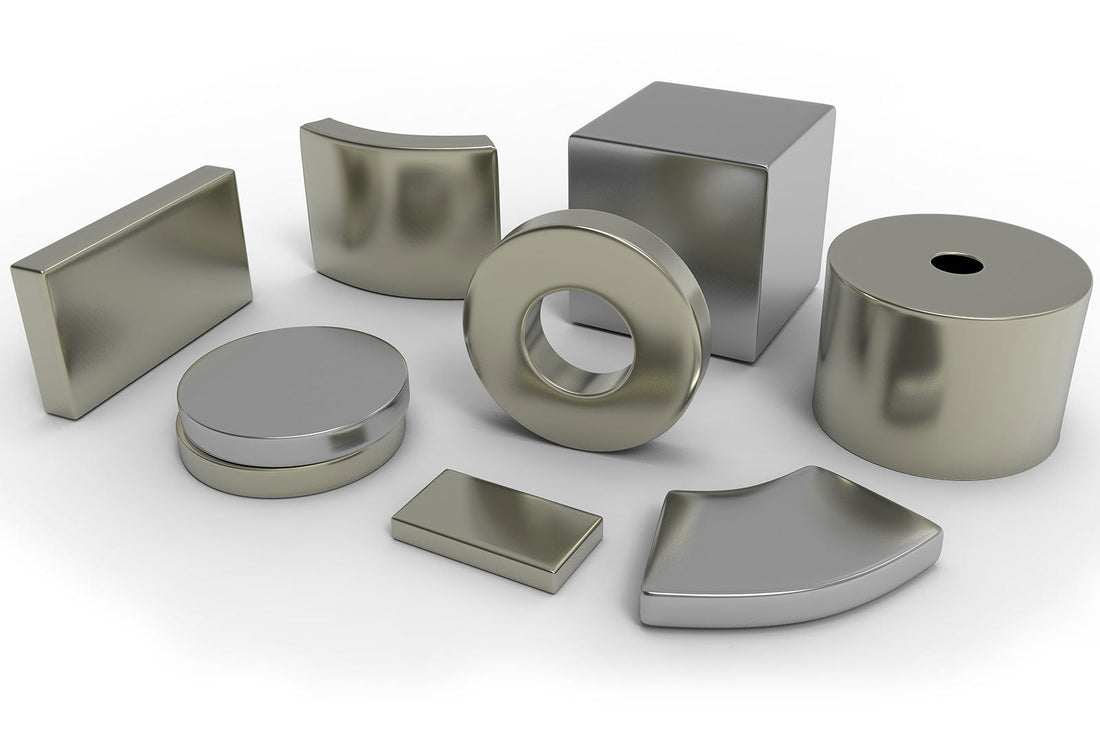

تعتبر مغناطيسات NDFEB N52 المكعبة مغناطيسات دائمة قوية مصنوعة من النيديميوم والحديد والبورون. هذه المغناطيسات الصغيرة معروفة بقوتها الكبيرة والعديد من استخداماتها. تعتبر N52 أعلى درجة لمغناطيسات النيديميوم حاليًا. إنها تعطي أقوى حقل مغناطيسي. يمكن لمغناطيسات NDFEB N52 المكعبة إنشاء حقول مغناطيسية تصل إلى 1.45 تسلا أو 14,800 غاوس. هذا أقوى بكثير من أنواع المغناطيس الأخرى. شكلها المكعب الصغير يجعلها مثالية للعديد من الاستخدامات في الصناعة والإلكترونيات ومشاريع المنزل.

| الخاصية | القيمة لمغناطيسات NDFEB N52 المكعبة |

|---|---|

| تركيب المواد | نيديميوم (Nd)، حديد (Fe)، بورون (B) |

| أقصى طاقة منتجة | 50-52 MGOe |

| مقاومة مغناطيسية (Br) | 14,200-14,800 غاوس |

| مقاومة (Hcb) | ≥11.6 kOe |

| أقصى درجة حرارة تشغيل | 80°C (176°F) |

| درجة حرارة كوري | 310°C (590°F) |

| الكثافة | 7.4-7.6 غرام/سم³ |

تستخدم مغناطيسات NDFEB N52 المكعبة كثيرًا في المحركات والمولدات وأجهزة الاستشعار وتقنيات الطاقة الخضراء. تساعد حقولها المغناطيسية القوية على التحكم بشكل جيد في الأمور وتحويل الطاقة بكفاءة في هذه الأجهزة. كما تستخدم مكبرات الصوت وسماعات الرأس وملحقات الهواتف مغناطيسات N52. هذه المغناطيسات صغيرة لكنها قوية. يحب الهواة أيضًا استخدام هذه المغناطيسات. يصنعون تماثيل مغناطيسية وتجارب عائمة وغيرها من المشاريع الممتعة بها.

العلم وراء مغناطيسات NDFEB N52

تعتبر مغناطيسات NDFEB N52 المكعبة قوية جدًا. تحصل على قوتها من ما تصنع منه وكيفية تصنيعها. تحتوي هذه المغناطيسات على نيديميوم وحديد وبورون. عادة ما تكون النسبة الدقيقة 31% نيديميوم و66% حديد و1% بورون، بالإضافة إلى كميات صغيرة من عناصر أخرى.

تبدأ عملية تصنيع هذه المغناطيسات من إذابة المواد الخام معًا. ثم يتم تبريد السبيكة المنصهرة بسرعة لتشكيل رقائق. يتم طحن هذه الرقائق إلى مسحوق ناعم وضغطها لتشكيل تحت حقل مغناطيسي قوي. يتم تسخين المادة المضغوطة لدرجات حرارة عالية جدًا، حوالي 1000-1100°C، لدمج الجسيمات. في النهاية، يتم معالجة المغناطيس بالحرارة، وتشكيله بدقة، وتغليفه للحماية.

تأتي قوة مغناطيسات NDFEB N52 المكعبة من هيكلها البلوري. خلال عملية التصنيع، يتم محاذاة المجالات المغناطيسية في المادة، مما يخلق حقلًا مغناطيسيًا قويًا. يمكن أن تخزن مغناطيسات N52 مزيدًا من الطاقة المغناطيسية في مساحة أصغر من أي نوع آخر من المغناطيس.

| الخاصية | القيمة لمغناطيسات NDFEB N52 |

|---|---|

| أقصى طاقة منتجة (BHmax) | 50-52 MGOe |

| مقاومة مغناطيسية (Br) | 14,200-14,800 غاوس |

| مقاومة (Hcb) | ≥11.6 kOe |

تظهر درجة N52 مدى قوة المغناطيس. إنها أعلى درجة متاحة لمغناطيسات النيديميوم حاليًا. الدرجات الأدنى مثل N35 أو N42 ليست قوية لكن يمكن أن تعمل للاستخدامات الأقل تطلبًا.

تمتلك مغناطيسات NDFEB N52 المكعبة خصائص مغناطيسية مدهشة. متوسط ندرتها، الذي يقيس المغناطيسية المتبقية، يتراوح بين 14,200 و14,800 غاوس. يتيح هذا الندرة العالية إنشاء حقول مغناطيسية قوية. إن مقاومتها، التي تظهر مدى مقاومتها لإزالة المغناطيسية، تبلغ على الأقل 11.6 kOe.

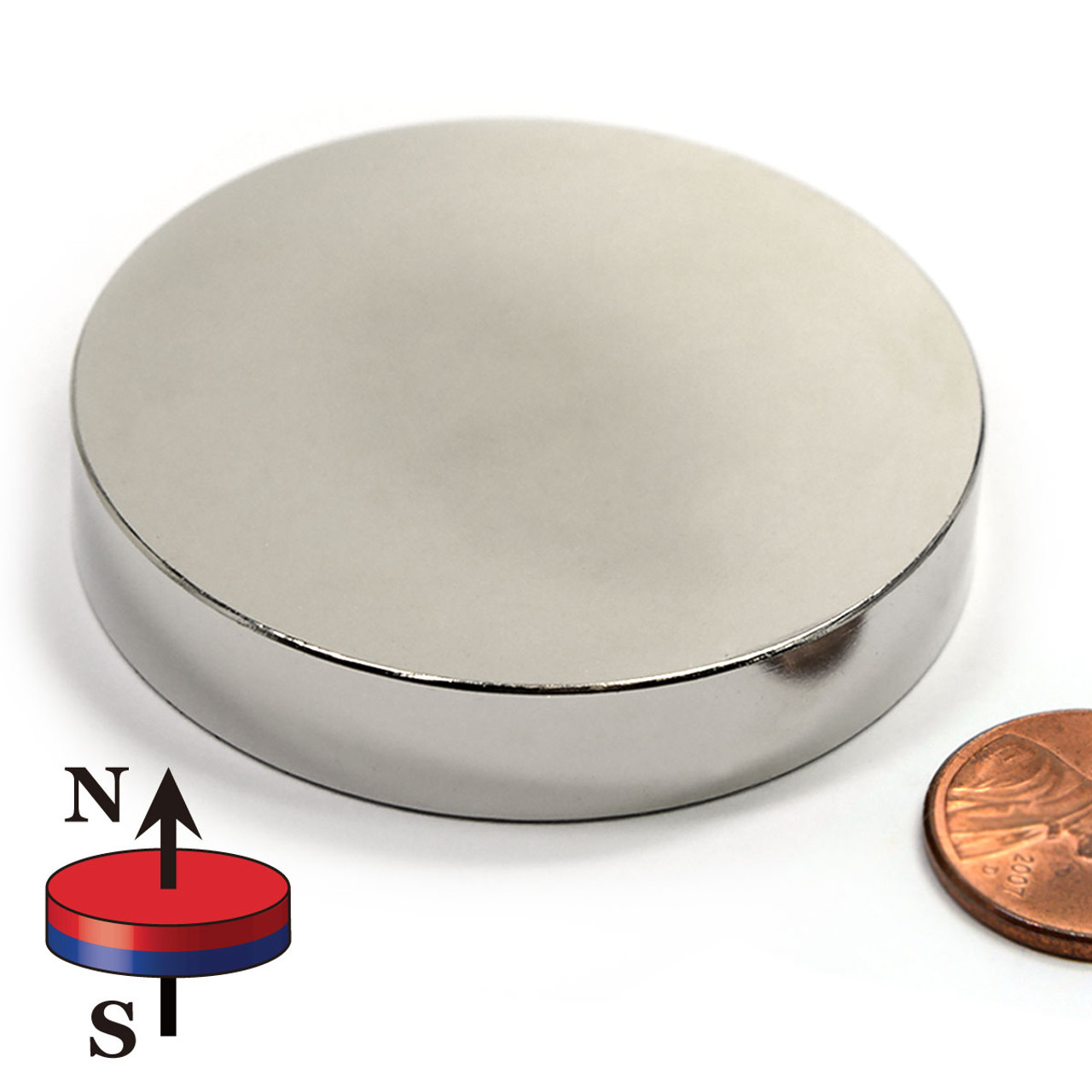

لنفهم مدى قوة هذه المغناطيسات، فكر في هذا: مكعب صغير بمقاس 1/2 بوصة يمكنه رفع أكثر من 30 رطلاً. هذا يجعلها أقوى بكثير من مغناطيس الفريت بنفس الحجم. نسبة القوة إلى الحجم تجعلها مثالية للاستخدامات التي تحتاج إلى حقول مغناطيسية قوية ولكن المساحة محدودة.

مزايا مغناطيسات NDFEB N52 المكعبة

تتمتع مغناطيسات NDFEB N52 المكعبة بالعديد من الفوائد. هذه المغناطيسات قوية جدًا بالنسبة لحجمها، مما يجعلها مفيدة بعدة طرق. يمكن لمغناطيس N52 بحجم 1 بوصة سحب أكثر من 100 رطل.

مغناطيسات NDFEB N52 المكعبة متينة أيضًا. تحتفظ بقوتها لفترة طويلة تحت الاستخدام العادي. معظم هذه المغناطيسات تحتوي على طلاء لمنع الصدأ وجعلها تدوم لفترة طويلة.

تتميز المغناطيسات المكعبة بوجود جوانب مسطحة تجعلها سهلة الاستخدام. يساعد هذا الشكل في الآلات وأجهزة الاستشعار. كما أن المغناطيسات المكعبة تتكدس بشكل جيد، مما يجعلها مناسبة للتخزين.

| الميزة | الوصف |

|---|---|

| القوة | قوة مغناطيسية عالية في حزمة صغيرة |

| الدوام | مقاومة لإزالة المغناطيسية والصدأ |

| الدقة | أسطح مسطحة لتسهيل التركيب والمحاذاة |

| التنوع | مناسبة لمجموعة واسعة من التطبيقات |

يمكن استخدام هذه المغناطيسات في العديد من المجالات. تعمل بشكل جيد في الإلكترونيات والطاقة الخضراء. تساعد حقولها القوية في توليد الطاقة في توربينات الرياح.

تعمل مغناطيسات N52 المكعبة بشكل جيد في درجات حرارة تصل إلى 80°C (176°F). هذا يجعلها جيدة للاستخدام في السيارات والمصانع. أما في الأماكن الأكثر حرارة، هناك أنواع خاصة من هذه المغناطيسات.

مغناطيسات NDFEB N52 المكعبة أفضل من الأنواع الأخرى. إنها أقوى بكثير من مغناطيسات الفريت أو AlNiCo من نفس الحجم. باستخدام هذه المغناطيسات يمكن أن تجعل الأجهزة أصغر وأخف وزناً.

التطبيقات الشائعة لمغناطيسات NDFEB N52 المكعبة

تحتوي مغناطيسات NDFEB N52 المكعبة على العديد من الاستخدامات في مختلف الصناعات. تلعب هذه المغناطيسات أدوارًا رئيسية في المحركات والمولدات للاستخدامات الصناعية. تساعد حقولها القوية على تحويل الطاقة بشكل جيد في هذه الآلات. تحتاج العديد من أجهزة الاستشعار أيضًا لمغناطيسات N52 المكعبة للعمل بشكل صحيح.

تستخدم الإلكترونيات الاستهلاكية غالبًا مغناطيسات NDFEB N52 المكعبة. تجعل مكبرات الصوت وسماعات الرأس تبدو جيدة مع الحفاظ على حجمها الصغير. تستخدم الأقراص الصلبة هذه المغناطيسات للتحكم بدقة في رؤوس القراءة/الكتابة. تحتوي الهواتف على مغناطيسات N52 صغيرة في مكبرات الصوت وأجزاء الاهتزاز.

تستخدم المجال الطبي مغناطيسات NDFEB N52 المكعبة بكثرة. تحتاج آلات التصوير بالرنين المغناطيسي إلى مغناطيسات نيديميوم كبيرة لعمل الصور. تستخدم بعض المعينات السمعية مغناطيسات N52 الصغيرة لتثبيت الأجزاء في مكانها. تساعد هذه المغناطيسات أيضًا في العديد من الأدوات الطبية الأخرى.

| الصناعة | التطبيقات |

|---|---|

| صناعي | محركات، مولدات، أجهزة استشعار |

| إلكترونيات | مكبرات الصوت، الأقراص الصلبة، الهواتف الذكية |

| طبي | آلات التصوير بالرنين المغناطيسي، المعينات السمعية |

| سيارات | محركات كهربائية، أجهزة استشعار |

| طاقة متجددة | توربينات الرياح، مولدات |

تحتاج السيارات إلى مغناطيسات NDFEB N52 المكعبة. تستخدم السيارات الكهربائية والهجينة هذه المغناطيسات في محركاتها. تعمل العديد من أجهزة استشعار السيارات بواسطة مغناطيسات N52. تشمل هذه أجهزة استشعار للموقع والسرعة والمكابح.

تعتمد الطاقة المتجددة على مغناطيسات NDFEB N52 المكعبة. تستخدم توربينات الرياح مغناطيسات نيديميوم الكبيرة لإنتاج الطاقة. كما تستخدم بعض أجهزة الطاقة الموجية الجديدة هذه المغناطيسات القوية. تساعد في تحويل الرياح والموجات إلى كهرباء.

يحب الهواة استخدام مغناطيسات NDFEB N52 المكعبة. يصنع الناس تماثيل مغناطيسية ولعب بهذه المغناطيسات. تعمل هذه المغناطيسات بشكل جيد في العديد من المشاريع، من البسيطة إلى المعقدة. قوتها تجعلها جيدة للاستخدامات الإبداعية.

تظهر مغناطيسات NDFEB N52 المكعبة في أماكن غريبة. تستخدم بعض بكرات الصيد هذه المغناطيسات للفرامل. تحتوي منتجات العلاج المغناطيسي غالبًا على هذه المغناطيسات، ولكن قد لا تعمل. يستخدم السحرة أحيانًا مغناطيسات N52 المكعبة في خدع تبدو مستحيلة.

اعتبارات التعامل والسلامة

تعتبر مغناطيسات NDFEB N52 المكعبة قوية جدًا. حقولها القوية يمكن أن تؤذيك إذا لم تكن حذرًا. يجب دائمًا إبقاء هذه المغناطيسات بعيدًا عن الأطفال والحيوانات الأليفة. عند العمل مع مغناطيسات N52 المكعبة، ارتدِ القفازات ونظارات السلامة.

قم بتخزينها بشكل صحيح. احتفظ بها في مكان بارد وجاف بعيدًا عن الإلكترونيات والأغراض المغناطيسية. افصلها لمنع التلف. استخدم فواصل غير مغناطيسية لمجموعات أكبر. تعتبر الصناديق الخشبية أو البلاستيكية جيدة للتخزين.

يمكن أن تؤذي هذه المغناطيسات الأجهزة الطبية. يجب على الأشخاص الذين لديهم أجهزة تنظيم ضربات القلب البقاء على بعد 6 بوصات على الأقل. قد تتداخل المغناطيسات مع هذه الأجهزة. استشر طبيبك إذا كنت قلقًا بشأن التعرض للمغناطيس.

| إجراء السلامة | الوصف |

|---|---|

| الحماية الشخصية | ارتدِ القفازات ونظارات الأمان |

| التخزين | استخدم حاويات غير مغناطيسية، احتفظ بالمغناطيسات مفصولة |

| الاحتياطات الطبية | ابتعد عن أجهزة تنظيم ضربات القلب والأجهزة المزروعة |

| التعامل | كن حذرًا لتجنب الضغط، والجذب المفاجئ |

| التخلص | اتبع اللوائح المحلية للنفايات الإلكترونية |

يمكن أن تضر مغناطيسات NDFEB N52 المكعبة الإلكترونيات. يجب إبقاؤها بعيدًا عن الكمبيوترات والهواتف وبطاقات الائتمان. يمكن أن تمحو حقولها القوية البيانات أو تفسد الأجهزة. تحقق مع شركات الطيران قبل الطيران مع هذه المغناطيسات. لدى بعض الشركات قواعد بشأن شحن المغناطيسات القوية.

لا تتخلص من هذه المغناطيسات في القمامة. تعتبر العديد من المناطق أنها نفايات إلكترونية. ابحث عن القواعد المحلية للتخلص السليم. ستأخذ بعض مراكز إعادة التدوير هذه المغناطيسات.

كن حذرًا عند التعامل مع العديد من مغناطيسات N52 المكعبة. يمكن أن تتشابك معًا بسرعة وتؤذيك أو تتكسر. استخدم أدوات غير مغناطيسية وسطح عمل. هذا يساعد على منع الحوادث ويحافظ على سلامة المغناطيسات.

اختيار مغناطيس NDFEB N52 المكعب المناسب

اختيار مغناطيس NDFEB N52 المكعب المناسب يتطلب عدة عوامل. الحجم مفتاح، حيث إنه يؤثر على قوة المغناطيس واستخدامه. تعمل المكعبات الصغيرة بشكل جيد في المهام الدقيقة، بينما تنتج المكعبات الأكبر مجالات مغناطيسية أقوى. كما أن الطلاء مهم أيضًا.

الطلاء النيكل يقاوم الصدأ، وطلاءات الإيبوكسي أو المطاط تضيف الحماية والقبضة. اتجاه التمغنط حاسم للأداء الجيد. يمكن تمغنطة مغناطيسات NDFEB N52 من خلال السماكة أو على قطر وجه. يعتمد الاختيار على كيفية تخطيطك لاستخدامه.

التمغنط المحوري غالبًا ما يكون أفضل للحقول المغناطيسية المركزة. يمكن أن يخلق التمغنط المائل أنماط حقول أكثر تعقيدًا.

| العامل | الاعتبارات |

|---|---|

| الحجم | متطلبات التطبيق، قيود المساحة |

| الطلاء | الظروف البيئية، احتياجات التعامل |

| التمغنط | اتجاه الحقل، تفاصيل التطبيق |

| الدرجة | متطلبات القوة، نطاق درجة الحرارة |

قوة السحب مهمة عند اختيار هذه المغناطيسات. تتغير حسب الحجم والدرجة. عادة ما يسحب مغناطيس N52 بحجم 1/2 بوصة حوالي 20-25 رطلاً. يمكن للمكعبات الأكبر سحب أكثر من 100 رطل.

اختر مغناطيسًا بالقوة المناسبة لاحتياجاتك. استخدام مغناطيس قوي جدًا يمكن أن يكون مكلفًا وغير آمن. تحتاج درجة الحرارة أيضًا إلى اعتبار عند اختيار المغناطيس. تعمل مغناطيسات N52 العادية بشكل جيد حتى 176°F.

بالنسبة للاستخدامات الأكثر حرارة، قد تحتاج إلى درجات خاصة مثل N52H أو N52SH. تحتفظ هذه بخصائصها المغناطيسية عند درجات حرارة عالية لكنها أضعف قليلاً. يعد قياس قوة المغناطيس أمرًا أساسيًا لمراقبة الجودة.

يمكن لأجهزة قياس جول أن تتحقق بدقة من قوة الحقل المغناطيسي. تُظهر أجهزة اختبار قوة السحب قياسات القوة العملية. تساعد هذه الأدوات في التأكد من أن المغناطيسات تلبي احتياجاتك.

يتطلب شراء مغناطيسات NDFEB N52 المكعبة الجيدة اختيار المورد بعناية. يصنع مصنعون جيدون مواصفات وشهادات مفصلة. من الحكمة اختبار نماذج المغناطيسات قبل شراء كميات كبيرة.

تعتبر المتاجر على الإنترنت سهلة، لكن تحقق من أن المغناطيسات حقيقية وعالية الجودة. غالبًا ما يرتكب الناس أخطاء عند اختيار هذه المغناطيسات. قد يختارون مغناطيسات قوية جدًا أو ضعيفة جدًا.

عدم التفكير في درجة الحرارة أو الرطوبة أو المواد الكيميائية يمكن أن يؤدي إلى فشل المغناطيس. من المهم مراعاة جميع هذه العوامل عند اختيار مغناطيسات NDFEB N52 المكعبة.

صيانة ورعاية مغناطيسات NDFEB N52 المكعبة

يعتبر التخزين المناسب أمرًا حيويًا للحفاظ على مغناطيسات NDFEB N52 المكعبة. احتفظ بها في مكان بارد وجاف بعيدًا عن الرطوبة والحرارة. للتخزين طويل الأمد، استخدم حاويات محكمة الغلق مع مواد ماصة للرطوبة لمنع الصدأ. افصل المغناطيسات الفردية بفواصل غير مغناطيسية لمنع التلف.

تنظيف مغناطيسات NDFEB N52 المكعبة يتطلب التعامل بلطف. استخدم قطعة قماش ناعمة وخالية من الوبر لإزالة الغبار والأوساخ. تجنب المواد الكيميائية القاسية أو المواد الخشنة التي قد تضر الطلاء. بالنسبة للأوساخ الصعبة، استخدم محلول صابون خفيف، ثم جفف المغناطيس جيدًا.

من الضروري منع إزالة المغناطيسية لهذه المغناطيسات القوية. احتفظ بها بعيدًا عن المجالات الكهرومغناطيسية القوية ودرجات الحرارة العالية. أعلى درجة حرارة آمنة لمغناطيسات N52 عادة ما تكون 80°C (176°F). يمكن أن يؤدي التعرض لدرجات حرارة أعلى إلى إضعاف المغناطيس إلى الأبد.

| جانب الرعاية | التوصية |

|---|---|

| التخزين | مكان بارد وجاف؛ استخدم مواد ماصة للرطوبة |

| التنظيف | قطع قماش ناعمة؛ صابون خفيف إذا لزم الأمر |

| درجة الحرارة | احتفظ بها تحت 80°C (176°F) |

| التعامل | استخدم أدوات غير مغناطيسية |

المعاينة المنتظمة تساعد في اكتشاف علامات التآكل أو التلف. ابحث عن الشقوق أو الكسور أو تغيرات اللون في الطلاء. قد تعني هذه علامات على أن المغناطيس يصدأ أو يتكسر. إذا رأيت أي تلف، استبدل المغناطيس للحفاظ على أدائه الجيد وسلامته.

تقنيات التعامل المناسبة تجعل مغناطيسات NDFEB N52 المكعبة تدوم لفترة أطول. استخدم أدوات غير مغناطيسية عند العمل معها لتجنب الحوادث والأضرار. احرص دائمًا على إبقاء المغناطيسات مفصولة أثناء النقل لمنع الشقوق أو الكسور من الاصطدام.

صيانة الطلاء أمر أساسي لطول العمر. معظم مغناطيسات NDFEB N52 المكعبة تحتوي على طبقة حماية من النيكل أو الإيبوكسي. تحقق من هذا الطلاء في كثير من الأحيان للبحث عن الخدوش أو التآكل. إذا كان الطلاء تالفًا، قد يتعرض المغناطيس للصدأ وسرعة التلف.

من خلال اتباع هذه نصائح العناية، يمكن لمغناطيسات NDFEB N52 المكعبة أن تبقى قوية لسنوات عديدة. تضمن الصيانة المنتظمة استمرارها في العمل بشكل جيد في العديد من الاستخدامات، من المصانع إلى المشاريع الهواية.

صيانة ورعاية مغناطيسات NDFEB N52 المكعبة

تضمن الرعاية المناسبة عمرًا طويلاً لمغناطيسات NDFEB N52 المكعبة. تحتاج هذه المغناطيسات القوية إلى ظروف تخزين محددة للحفاظ على قوتها. يعتبر المكان البارد والجاف هو الأفضل للحفاظ على خصائصها المغناطيسية. يمكن أن تسبب الرطوبة صدأًا، حتى مع وجود طلاءات وقائية على المغناطيسات.

يساعد استخدام مواد ماصة للرطوبة في حاويات التخزين. تنظيف هذه المغناطيسات سهل ولكنه يحتاج إلى عناية. تعمل قطعة قماش ناعمة وخالية من الوبر بشكل جيد لإزالة الغبار. لا تستخدم الماء أو منتجات التنظيف إذا استطعت تجنب ذلك.

إذا لزم الأمر، يمكنك استخدام قطعة قماش رطبة، لكن تأكد من تجفيف المغناطيسات على الفور. التحكم في درجة الحرارة مهم جدًا لهذه المغناطيسات. يمكن لمغناطيسات NDFEB N52 أن تفقد قوتها إذا ارتفعت درجات الحرارة بشكل كبير.

تعتبر أعلى درجة حرارة آمنة عادة هي 80°C (176°F). تجاوز ذلك يمكن أن يضعف المغناطيس بشكل دائم. من الضروري مراقبة درجة الحرارة في الأماكن التي قد تكون فيها الحرارة مشكلة.

تساعد الفحوصات المنتظمة في الكشف عن المشاكل مبكرًا. ابحث عن أي تلف في الطلاء أو علامات صدأ. يمكن أن تسمح الشقوق أو الكسور الصغيرة بدخول الهواء والرطوبة إلى مادة المغناطيس. يمكن أن تؤدي هذه إلى إضعاف المغناطيس بسرعة.

استبدل المغناطيسات التالفة بسرعة للحفاظ على أداء نظامك بشكل جيد. يتطلب التعامل مع هذه المغناطيسات أدوات وطرق خاصة. استخدم أدوات بلاستيكية أو ملاقط غير مغناطيسية عند العمل معها.

هذا يمنع الالتصاق غير المقصود والإضرار المحتمل. احرص دائمًا على إبقاء المغناطيسات مفصولة خلال النقل أو التخزين. يمكن أن تؤدي الاصطدامات المفاجئة بين المغناطيسات إلى الشقوق أو الكسور.

صيانة الطلاء أمر رئيسي لتحقيق أداء طويل الأمد. تحتوي معظم مغناطيسات NDFEB N52 المكعبة على طلاء من النيكل أو الإيبوكسي. تعمل هذه الطبقة على حماية المغناطيس من الصدأ والأضرار الجسيمة. تحقق من الطلاء بشكل متكرر بحثًا عن أي تآكل.

إذا كان الطلاء تالفًا، فكر في إعادة الطلاء أو استبدال المغناطيس. يمكن أن تساعد اتباع هذه نصائح الصيانة مغناطيسات NDFEB N52 المكعبة في البقاء قوية لسنوات. تضمن الصيانة الجيدة استمرارها في العمل بشكل جيد في العديد من الاستخدامات.

تعتبر هذه المغناطيسات مهمة في التكنولوجيا الحديثة، من الآلات الكبيرة إلى الإلكترونيات الصغيرة.